Automotive aluminium

Automotive aluminium: Driving innovation in the automotive industry

In the growing automotive industry, lightweight materials have become a driving force for innovation. Aluminium is a lightweight and durable metal that offers a wide range of benefits to the automotive industry. Here are some of the reasons why car manufacturers are increasingly adopting aluminium products:

1. Weight reduction

One of the main advantages of using aluminium in automotive manufacturing is its low density. It is much lighter than steel and helps reduce the total weight of the car. The reduced weight helps to improve fuel efficiency and reduce emissions.

2. Improved performance

Lighter vehicles require less energy to operate. The use of aluminium in key areas such as the chassis, body panels and engine components saves significant amounts of fuel, which improves the overall performance of the vehicle. Reduced weight results in better acceleration, handling and braking, which enhances the driving experience.

3. Corrosion resistance

Aluminium is highly resistant to corrosion as it naturally forms a protective oxide layer. This longevity ensures that aluminium automotive components last longer and require less maintenance.

4. Recyclability

Aluminium can be fully recycled without any loss of quality. This sustainability factor is in line with the automotive industry’s growing commitment to environmental protection.

Applications: Aluminium is used in a wide range of automotive components to improve efficiency, safety and aesthetics:

1. Body panels

Aluminium is used to manufacture body panels, including doors, bonnets and boots. These lightweight panels reduce the overall weight of the vehicle while maintaining structural integrity.

2. Engine components

Aluminium is used in engine components such as cylinder heads, engine blocks and pistons. Its thermal conductivity helps dissipate heat efficiently, thus improving engine performance.

3. Wheels

Aluminium wheels are popular for their light weight and stylish design. They enhance the aesthetics of the vehicle while reducing the unsprung weight, which has a positive impact on handling and ride quality.

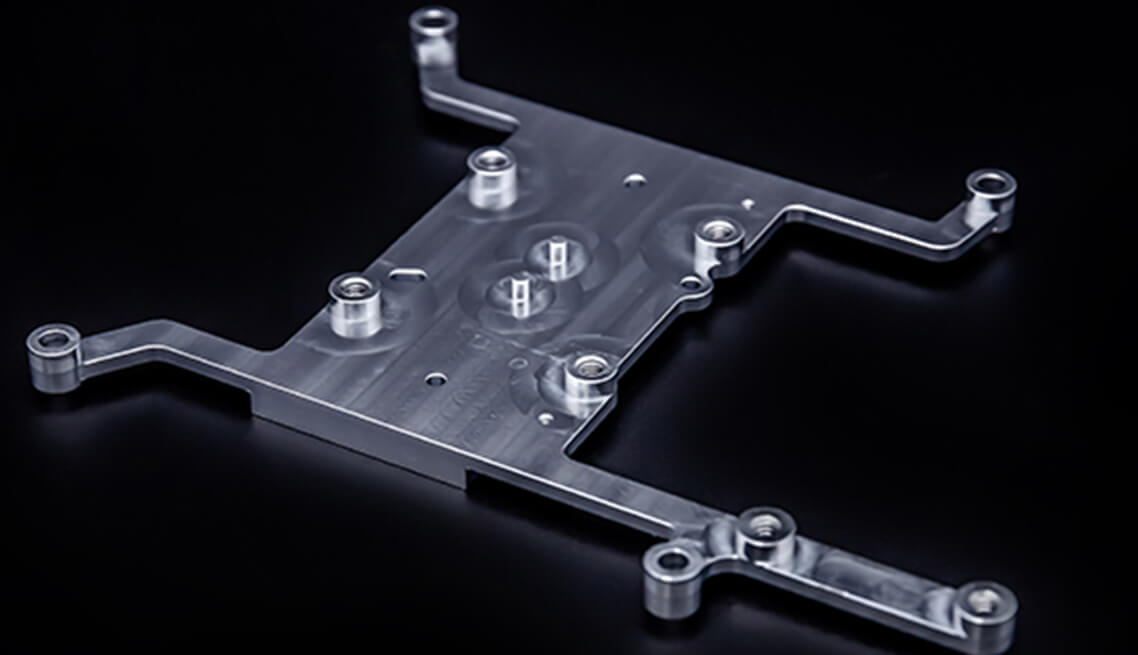

4. Chassis and frames

Aluminium is used in the manufacture of automotive chassis and frames, providing high strength and stiffness. This improves safety and structural integrity.

5. Interior components

Aluminium is also used in interior components, including instrument panels, trim and seat structures. Its lightweight and aesthetic features enhance the overall interior design.

The future of automotive aluminium

The use of aluminium in automobiles is expected to grow as automakers continue to prioritise lightweight materials and sustainability. Innovations in aluminium alloys and manufacturing processes will further optimise the strength, durability and cost-effectiveness of aluminium.

In short, automotive aluminium products have revolutionised the automotive industry by combining lightweight construction, fuel efficiency and durability. As the automotive industry moves towards a greener, more efficient future, aluminium will continue to play a key role in shaping the cars we drive – contact us to get the automotive aluminium products you need to be safer, more aesthetically pleasing and more technologically advanced.