Aluminium begins as a raw material in various forms, such as sheets, extrusions or castings. Equipment processes this material by cutting, forming or heating it to achieve the required dimensions and properties.

Our skilled operators manage the equipment using computerised control systems to ensure accuracy. They monitor parameters such as speed, pressure and temperature, making adjustments as needed during the manufacturing process. Quality control measures are strictly enforced, which includes the use of measuring tools, visual inspections and testing methods to verify that the finished product meets the required standards.

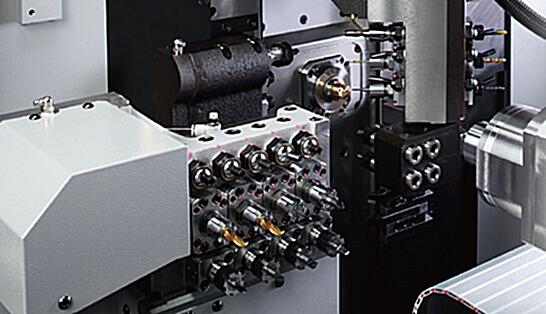

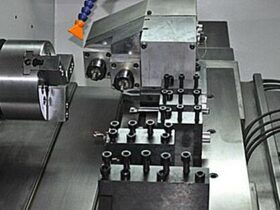

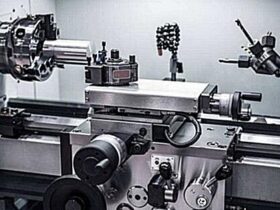

ALUMINIUM EQUIPMENT

ALUMINIUM EQUIPMENT

FREQUENTLY ASKED QUESTIONS (FAQ):

The following are some of the frequently asked questions about aluminium products and their answers:

SERVICES OFFERED

Aluminium product processing facilities offer a wide range of services to meet the diverse needs of industries around the world:

Custom Manufacturing: Provides custom aluminium product manufacturing services based on the unique requirements of customers in industries such as aerospace, automotive, electronics and construction.

Prototyping: Save time and resources by offering prototyping services to test and refine new product designs before full-scale production.

Materials Expertise: Providing guidance on selecting the right aluminium alloys and profiles based on factors such as strength, corrosion resistance and weight to ensure optimum performance.

Surface treatments: We offer a variety of surface treatment options such as anodising, powder coating and polishing to enhance the appearance and functionality of aluminium products.

Value-added services: In addition to production, the company can provide additional services such as assembly, packaging and logistics support to provide customers with comprehensive solutions.