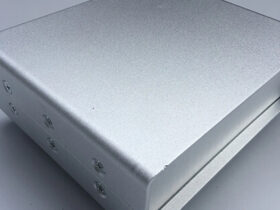

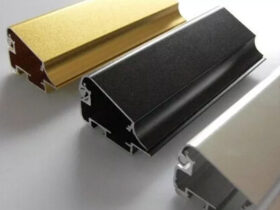

Aluminium surface technology plays a vital role in improving the appearance, functionality and durability of aluminium products. The natural properties of aluminium make it corrosion resistant and lightweight, but surface treatments can further improve its properties.

Surface treatment technologies can improve the appearance of aluminium products, offering a wide range of options such as polished, matt or textured, which can increase the hardness and wear resistance of aluminium, form a protective layer, enhance the corrosion resistance of aluminium and extend the life of the product. Certain surface treatments (e.g. anodising) can also be used to improve the electrical conductivity of aluminium components.