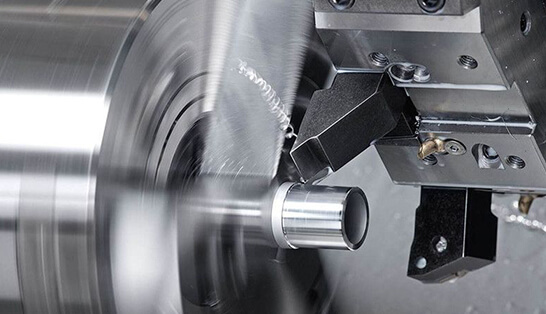

Machining technology is primarily concerned with the removal of material from aluminium workpieces to obtain precise shapes and dimensions. The machining process begins with a detailed computer-aided design (CAD) model of the required aluminium part. A skilled machinist then selects the appropriate cutting tools and fixtures for the specific requirements of the project. Finally the movements of the cutting tools are controlled with great precision by computer numerical control (CNC) machines under the guidance of programmed instructions. They remove material from aluminium workpieces according to CAD models.

PROCESSING TECHNOLOGY

PROCESSING TECHNOLOGY

SERVICE DETAILS

Here are common questions and answers related to aluminum products and the machining process:

SERVICES OFFERED

Custom parts: Custom aluminium parts can be produced for industries such as aerospace, automotive, electronics and mechanical engineering.

Prototyping: Machining is used to create prototypes of new aluminium products for testing and refinement prior to full-scale production.

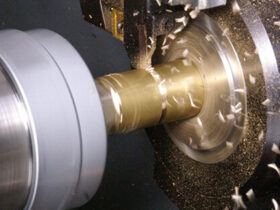

Precision parts: This is key to the manufacture of high-precision aluminium parts such as engine components, aircraft fittings and complex structural parts.

Surface Finishes: Machining techniques can achieve a wide range of surface finishes and are therefore suitable for aesthetically pleasing applications.

We at JLX take quality control measures throughout the machining process, including measurements and inspections, to ensure that the dimensions and surface finish of aluminium parts meet the specified requirements.