Non-Standard Aluminium

Non-standard aluminium: Breaking the mould, pioneering innovation

In materials engineering and manufacturing, pushing the boundaries of innovation often requires breaking with standard conventions. Non-standard aluminium, often referred to as bespoke or unconventional aluminium, is at the forefront of this trend. Challenging conventional ideas about what aluminium can achieve, this unconventional approach to aluminium production is significant for several reasons:

1. Customisation

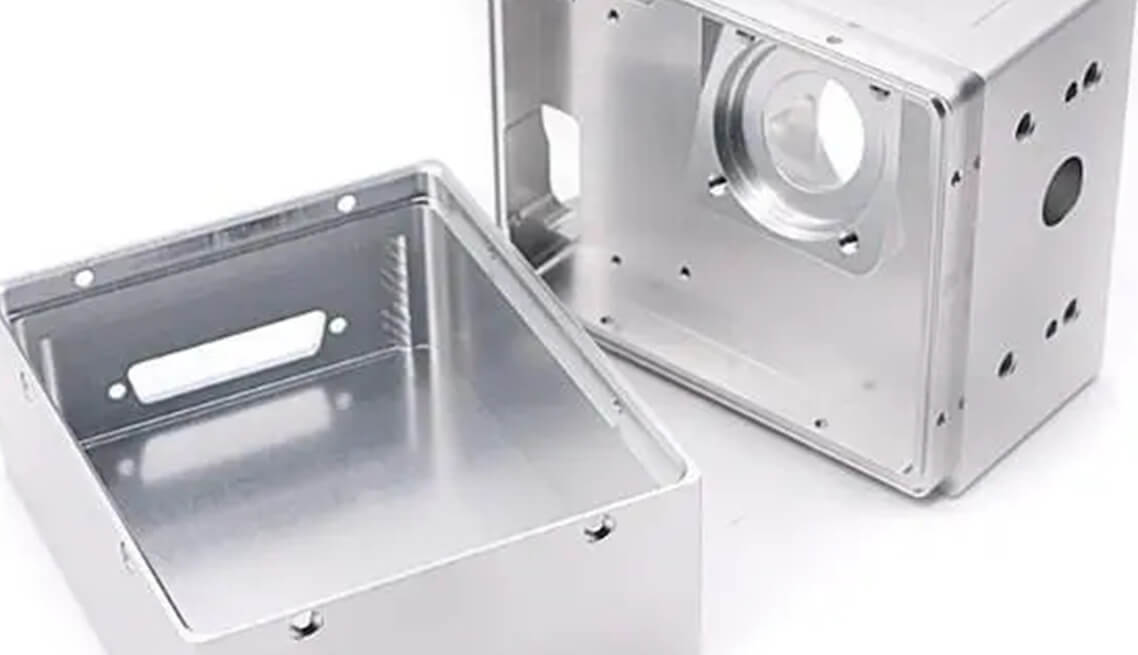

Non-standard aluminium is highly customisable, allowing engineers and manufacturers to tailor components and structures to specific applications. This customisation can provide unique solutions that would be difficult or impossible to achieve using standard materials.

2. Innovation

Non-standard aluminium encourages engineers and designers to think outside the box, which drives innovation. It opens up new possibilities for creating lightweight, strong and aesthetically pleasing products that challenge the status quo.

3. Solving problems

In many cases, standard aluminium may not be able to meet the requirements of complex or specialist projects. Non-standard aluminium addresses these challenges by providing materials that can meet the unique needs of a project.

4. Versatility

It comes in a variety of forms, including complex geometries, profiles and alloys. This versatility allows it to be used in a variety of industries, from cutting-edge construction to advanced aerospace applications.

It can be used in a wide range of industries and environments:

1. Aerospace

In the aerospace industry, where weight reduction is critical, bespoke aluminium components are used in aircraft and spacecraft to achieve the best strength-to-weight ratio.

2. Architecture

Architects and builders use non-standard aluminium to create distinctive building facades, unconventional structural elements and art installations that challenge traditional design codes.

3. Automotive

In the automotive sector, non-standard aluminium components are used to enhance vehicle performance, improve fuel efficiency and enable innovative designs.

4. industrial manufacturing

In industrial manufacturing, components can be tailored to fit specialised machinery and equipment to optimise processes and improve efficiency.

5. Research and development

Research institutes and laboratories use non-standard aluminium in customised experimental set-ups and prototypes to advance scientific and technological discoveries.

Conclusion

Non-standard aluminium is a driving force for innovation in materials engineering and manufacturing. Its customisability, versatility and problem-solving capabilities enable industries and individuals to challenge convention and create solutions that push boundaries. As industries continue to evolve and seek new approaches, it is an invaluable resource for shaping the future of technology, design and engineering.